I just started offering free consulting services to makers that are building (or already running) a small manufacturing business to sell their own product. If that's you, check out the details and get in touch!

Updates

(subscribe to news feed)I have a daily habit of working on side projects, and I've come to appreciate the benefits of tracking that habit out in the open. If I'm doing work on a software project, I track that on GitHub. If it's more hands-on, I like to post an update here.

-

-

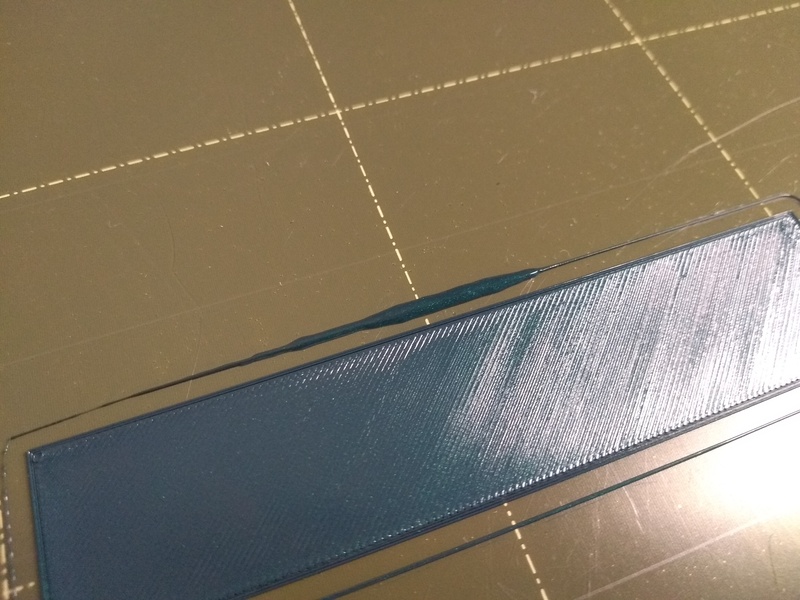

The printer problems are never-ending! Now I'm seeing these blobby beads. Fortunately only in skirts so far, not in any print itself. My theory is that this was caused by the Mini's built-in first-layer calibration procedure.

I currently have a 0.25mm nozzle equipped, but the first-layer calibration assumes a 0.4mm nozzle, which could theoretically lead to excess material in the nozzle/hotend. If that's true, this will hopefully clear up soon. That, or I'll need to do more cold pulls...

-

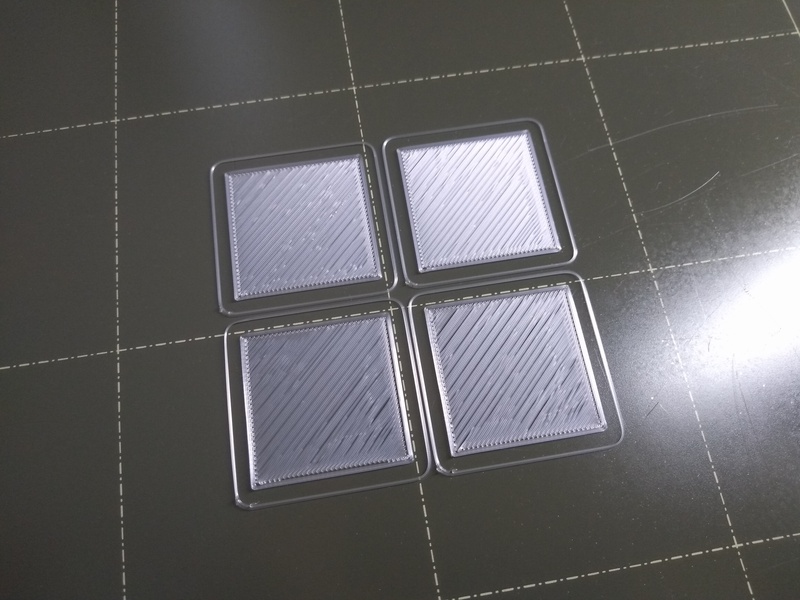

I'm still working on my printing issues. This picture shows some test prints consisting of only a first layer. I first thought those gaps between the layers were a sign of a partially clogged nozzle, but looking at it more closely, there seems to be a continuous extrusion.

Not sure what this means. Possibly under-extrusion, possibly a wrong value for extrusion width. In any case, I've decided to ignore the NonOilen for now and focus on getting the printer working with the Prusament PLA that I've been printing all this time.

-

Got some new tools for the home workshop! I need exactly one specific wrench and socket right now, but who doesn't like an excuse to buy a whole set.

-

On the plus side, I've received some new nozzles that I ordered last week. I need the smallest one to solve the problem with the inner diameter problem of the spacer. The other ones should come in handy once I want to print something larger again.