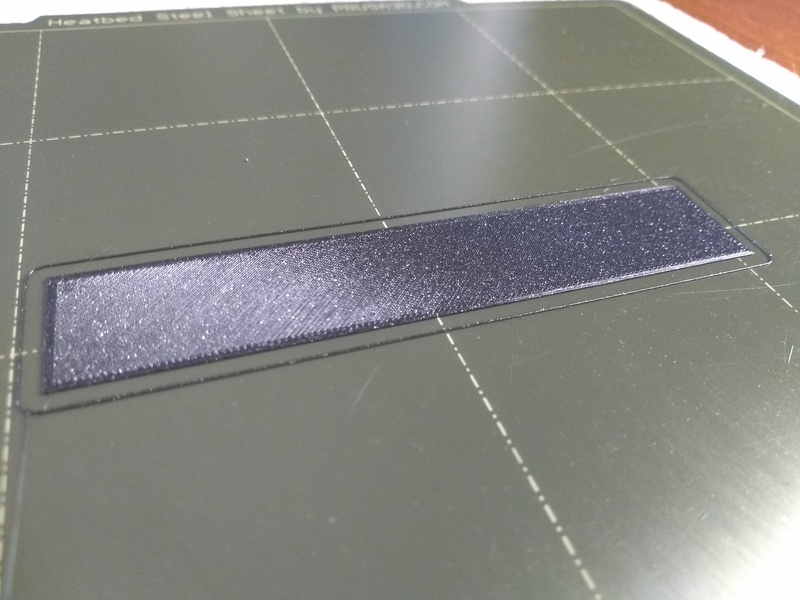

The trend continues. Every attempted solution to a problem creates new ones. Now I'm having issues with z-axis calibration. It's out of calibration, I adjust over a few prints, now everything's great. Then, for next day's first print, it's out of calibration again.

I figured that maybe, due to the new improvised enclosure, the printer heats up over a few prints, causing the z-axis to expand. And in fact, some calculation based on plausible guesstimates tells me the aluminium extrusion that holds the z-axis might grow by 0.13mm. That's more than half the first layer height, and about the same as my adjustment to the z-offset value.

But of course, if the z-axis grows, the z-position should be too low for the first print, which is the exact opposite of what I'm seeing. After many weeks of this kind of stuff, I'm so thoroughly confused.